The Bullet Blender Stands Out Among Bead Mill Homogenizers

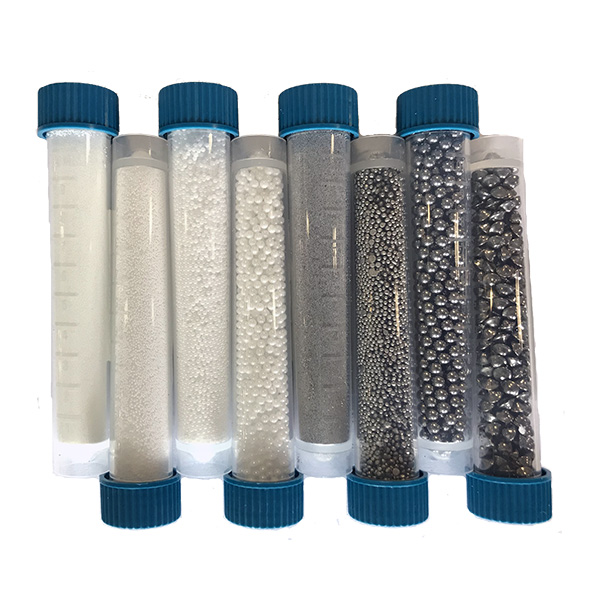

Bead mill homogenizers lyse cells by agitating samples in tubes filled with beads. The vigorous agitation causes beads to collide with the samples, physically lysing them. The Bullet Blender is a bead mill homogenizer that uses beads to strike and grind your samples inside a sample tube. By selecting the appropriate size and material of beads, you can successfully process a wide array of samples for various applications, such as creating single-cell suspensions, lysing whole tissue, or isolating bacteria from whole tissue. Alternatively, bead lysis kits (sample tubes pre-filled with beads) can be used to remove the guesswork from bead selection.

Unlike most bead mill homogenizers that clamp sample tubes in a holder and vigorously shake the holder, the Bullet Blender agitates every sample tube independently. Consequently, this allows for convective air flow around each sample tube to remove heat, preventing excessive temperature rise during homogenization.

Using the Bullet Blender bead mill homogenizer ensures efficient cell disruption and optimal recovery of biomolecules, making it a preferred choice for various applications.

Bead Selection for Homogenization

When choosing beads for homogenizing your sample, consider the following factors to achieve the best results:

- Select denser beads for tougher samples to generate more energetic impacts during homogenization. For instance, stainless steel beads work particularly well for tough samples.

- Opt for smaller beads for tiny samples and cell culture to ensure thorough homogenization.

- Choose larger beads for tough samples and special applications for effective grinding and slicing. Stainless steel beads with a ridge, known as “UFO” shapes, are especially beneficial for such purposes.

To simplify your bead selection, explore our Bead Sample Packs and Bead Lysis Kits. The pre-filled bead lysis kits include optimized bead combinations for various sample types, saving you time on method optimization.

Why Bead Size and Shape Matter

During vigorous agitation, denser beads generate greater momentum, resulting in more effective homogenization. The size and shape of the beads are crucial in achieving optimal results. Alternative bead shapes, like the “UFO” design, can enhance the homogenization process by providing efficient slicing and grinding.

Streamline your experiments with Proven Protocols

Our protocols are designed for various sample types, allowing you to focus more on obtaining results and less on optimization. Visit our protocol page for more information and to find the right protocol for your needs.

By selecting the appropriate bead composition, size, and shape, you can ensure efficient and effective homogenization for a wide range of samples.

Maintain Sample Temperatures at 4°C

During homogenization, your samples can heat up locally due to internal vibrations and friction between the beads and samples. Unlike competing homogenizers, Bullet Blender® Gold+ keeps samples at 4°C using an integrated cooling system.

The Gold+ cooling system monitors how hard the motor is working and adjusts the flow of air past the dry ice or liquid nitrogen and then past the sample tubes. The air removes heat as it travels past the sample tubes, maintaining the ideal temperature. Whether you use liquid nitrogen or dry ice, the Gold+ accommodates both cooling options, giving you the flexibility to choose whichever is available or more convenient.